One Board Supporting the Sky

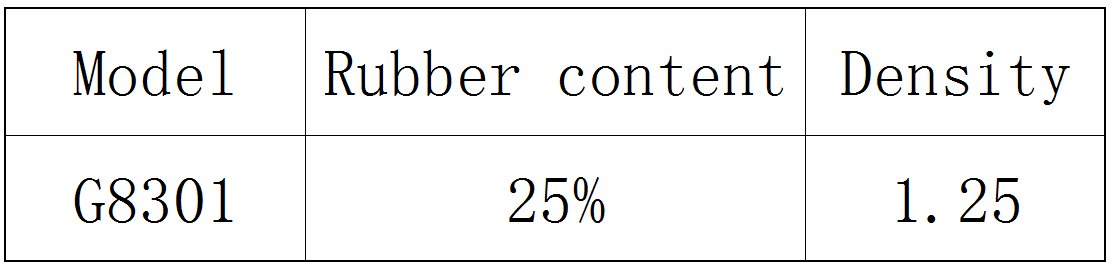

Factory Cheap Smart Film Packaging - G1031 Butyl Adhesive with Rubber Content Up to 25% – Gooban

Factory Cheap Smart Film Packaging - G1031 Butyl Adhesive with Rubber Content Up to 25% – Gooban Detail:

Introduction To Production Line

The company now has 10 domestic advanced production lines for mixing butyl rubber, with an annual output of 10000 tons. The patented formula is provided by Qingdao University of science and technology. After special process flow, its products have excellent adhesion, weather resistance, aging resistance and excellent waterproof and sealing properties.

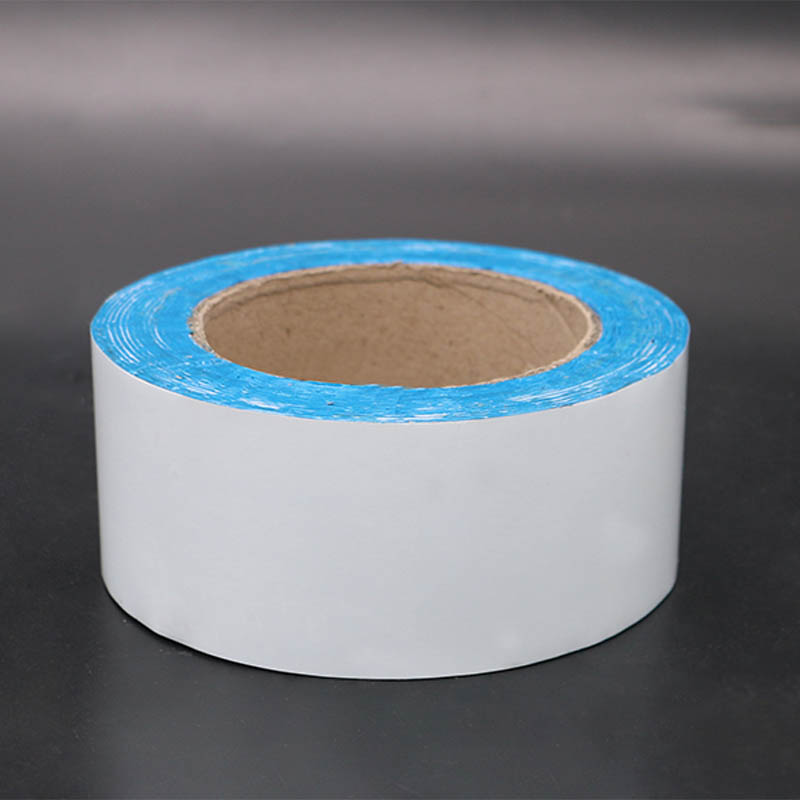

It is mainly used for waterproof butyl tape coating, single-sided and double-sided self-adhesive waterproof coiled material coating, lap tape coating, etc., and can be produced according to the color specified by customers.

Rubber Mixing Process Conditions

Butyl rubber has low cohesion and poor self-adhesive property. The rubber is easy to be broken, and the process of regrouping into a whole is very slow. Therefore, higher mixing temperature and longer mixing time are required during mixing. During the mixing process, 2ylyy114wfm paid attention to the change of mixing temperature in time and strictly controlled the mixing temperature to avoid the influence of too high or too low temperature on the quality of mixed rubber and finished products. When butyl rubber is mixed by internal mixer, the mixing temperature is generally controlled at 150 ° C to promote the uniform dispersion of the compounding agent.

Internal mixer mixing: when mixing butyl rubber with internal mixer, properly increase the rubber loading capacity, which is greater than 10% – 20% of natural rubber; The pressure of upper top bolt is higher than that of lower top bolt during mixing. When the amount of compounding agent used in the formulation of butyl rubber products is large, two-stage mixing method or reverse mixing method can be used for the mixing process.

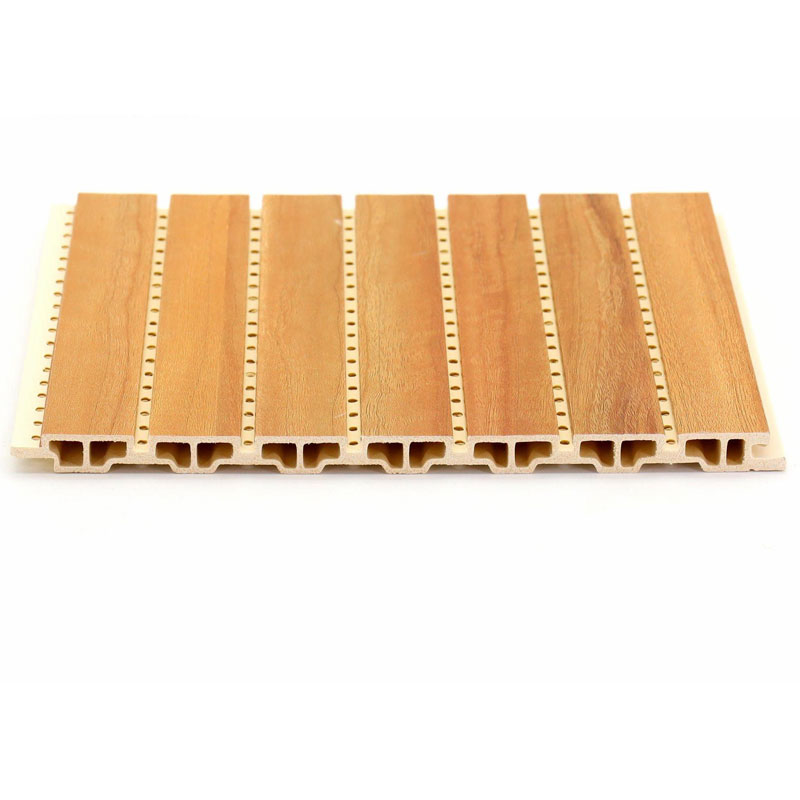

Product detail pictures:

Related Product Guide:

In an effort to finest meet up with client's requirements, all of our operations are strictly performed in line with our motto High High quality, Competitive Rate, Fast Service for Factory Cheap Smart Film Packaging - G1031 Butyl Adhesive with Rubber Content Up to 25% – Gooban , The product will supply to all over the world, such as: Florida, South Korea, Malta, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.