One Board Supporting the Sky

Free Sample For Shrink Wrap Plastic Rolls - Aluminum Foil with Customizable Thickness And Color – Gooban

Free Sample For Shrink Wrap Plastic Rolls - Aluminum Foil with Customizable Thickness And Color – Gooban Detail:

Product Characteristics

The advantage of aluminum foil composite material is that it can block oxygen and moisture well, and the water permeability and oxygen permeability are both 1, so it is a good barrier material. In addition, aluminum foil has good heat resistance, good light reflection and gloss, and good shape at high and low temperatures. The aluminum foil itself is waterproof, airtight and light tight. It can protect the butyl adhesive layer from environmental impact and greatly improve its natural aging resistance.

Aluminum foil is a perfect material with many excellent properties, which fully shows its broad application prospects in many fields.

Processing Status

According to the processing status, aluminum foil can be divided into plain foil, embossed foil, composite foil, coated foil, colored aluminum foil and printed aluminum foil.

① Plain foil: aluminum foil without any other processing after rolling, also known as light foil.

② Embossed foil: aluminum foil with various patterns pressed on the surface.

③ Composite foil: composite aluminum foil formed by laminating aluminum foil with paper, plastic film and paperboard.

④ Coated foil: aluminum foil coated with various resins or paints.

⑤ Colored aluminum foil: aluminum foil coated with a single color on the surface.

⑥ Printed aluminum foil: aluminum foil that forms various patterns, patterns, characters or pictures on the surface by printing. It can be one color, up to 12 colors.

Soft aluminum foil can also be further pressed into 40 foil for high-end decoration.

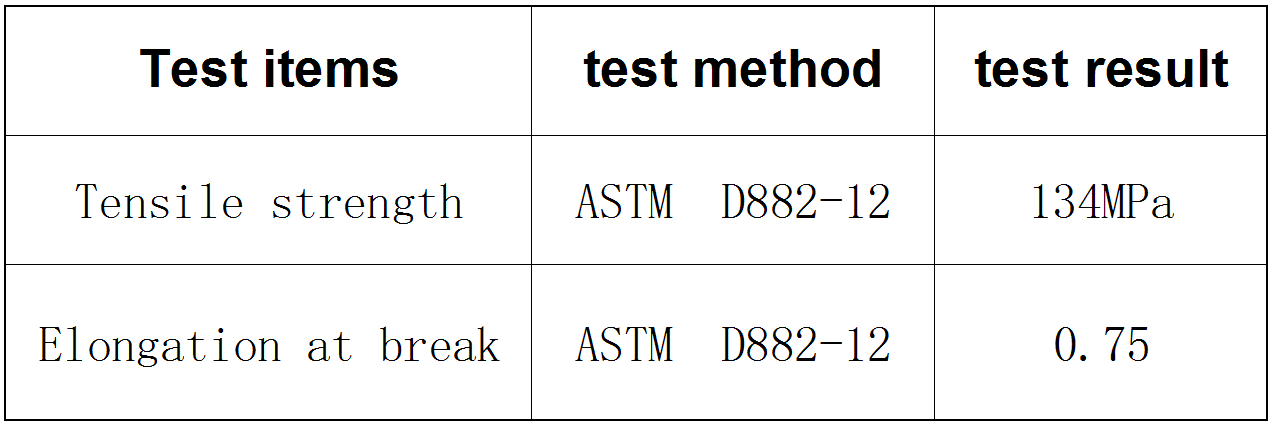

Performance Index Test

Sample width: 15mm

Sample thickness: 0.026mm

Test speed: 50mm/min

Collet distance: 100mm

Laboratory environmental conditions: (23 ± 2) ° C, (50 ± 5)%rh

Product detail pictures:

Related Product Guide:

The corporation upholds the philosophy of Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth, will proceed to provide aged and new buyers from home and abroad whole-heatedly for Free Sample For Shrink Wrap Plastic Rolls - Aluminum Foil with Customizable Thickness And Color – Gooban , The product will supply to all over the world, such as: London, Zambia, America, Welcome to visit our company and factory, there are various products displayed in our showroom that will meet your expectation, meanwhile, if you are convenient to visit our website, our sales staff will try their efforts to provide you the best service

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!