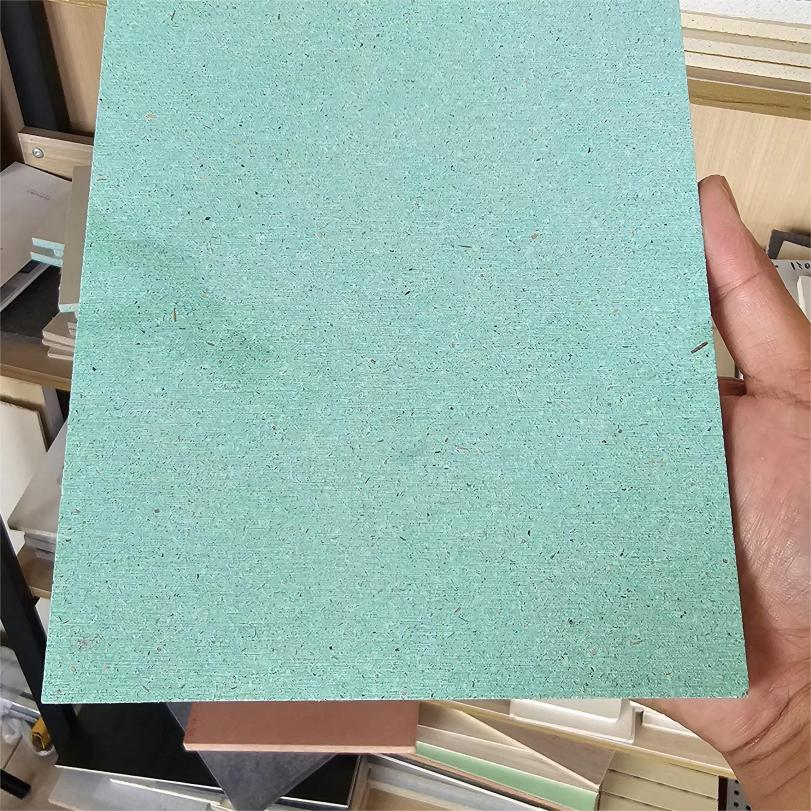

Some clients customize the color of magnesium oxide sulfate boards for different application scenarios, with common colors being gray, red, green, and white. Generally, the entire board can only present one color. However, for special purposes or marketing needs, businesses sometimes require the front and back of the magnesium oxide sulfate board to have different colors. This requires mixing different pigments into the raw materials during the layering process.

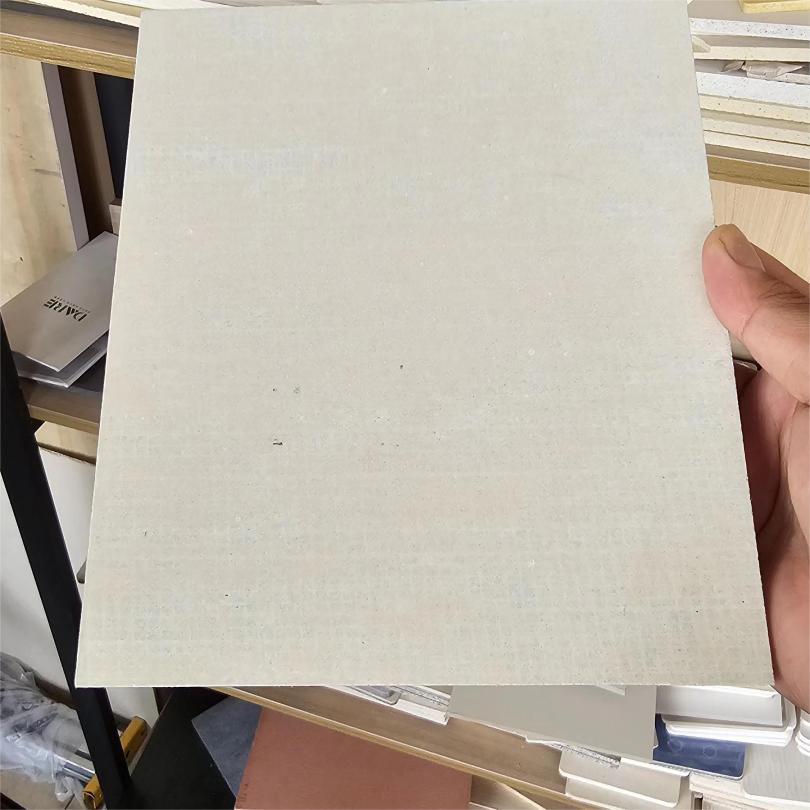

For example, a recent order required the smooth side of the magnesium oxide sulfate board to be white and the back side to be green. Because the smooth side would be used to apply a thin decorative film, a dark color might affect the appearance of the decorative surface, so white was chosen for the smooth side. Theoretically, this color mixing process in production is simple—just mix different colors in the top and bottom layers. However, in practice, it's essential to consider the white color of the smooth side, which is part of the bottom layer and sits at the bottom of the mold during forming, leading to a color seepage process. This challenges the color mixture of the textured side, as the concentration needs to be carefully controlled to prevent the green color from seeping into the bottom layer and contaminating the white surface.

Post time: Jun-12-2024