In the production process, controlling the evaporation rate of moisture during curing is key to ensuring that magnesium boards do not deform or have minimal deformation. Today, we will focus on how to handle magnesium boards during transportation, storage, and installation to avoid deformation issues.

Due to the unique production process of magnesium boards, the density and material usage of the front and back sides of the boards cannot be consistent without incurring high costs. Therefore, some degree of deformation in magnesium boards is unavoidable. However, in construction, it is sufficient to keep the deformation rate within an acceptable range.

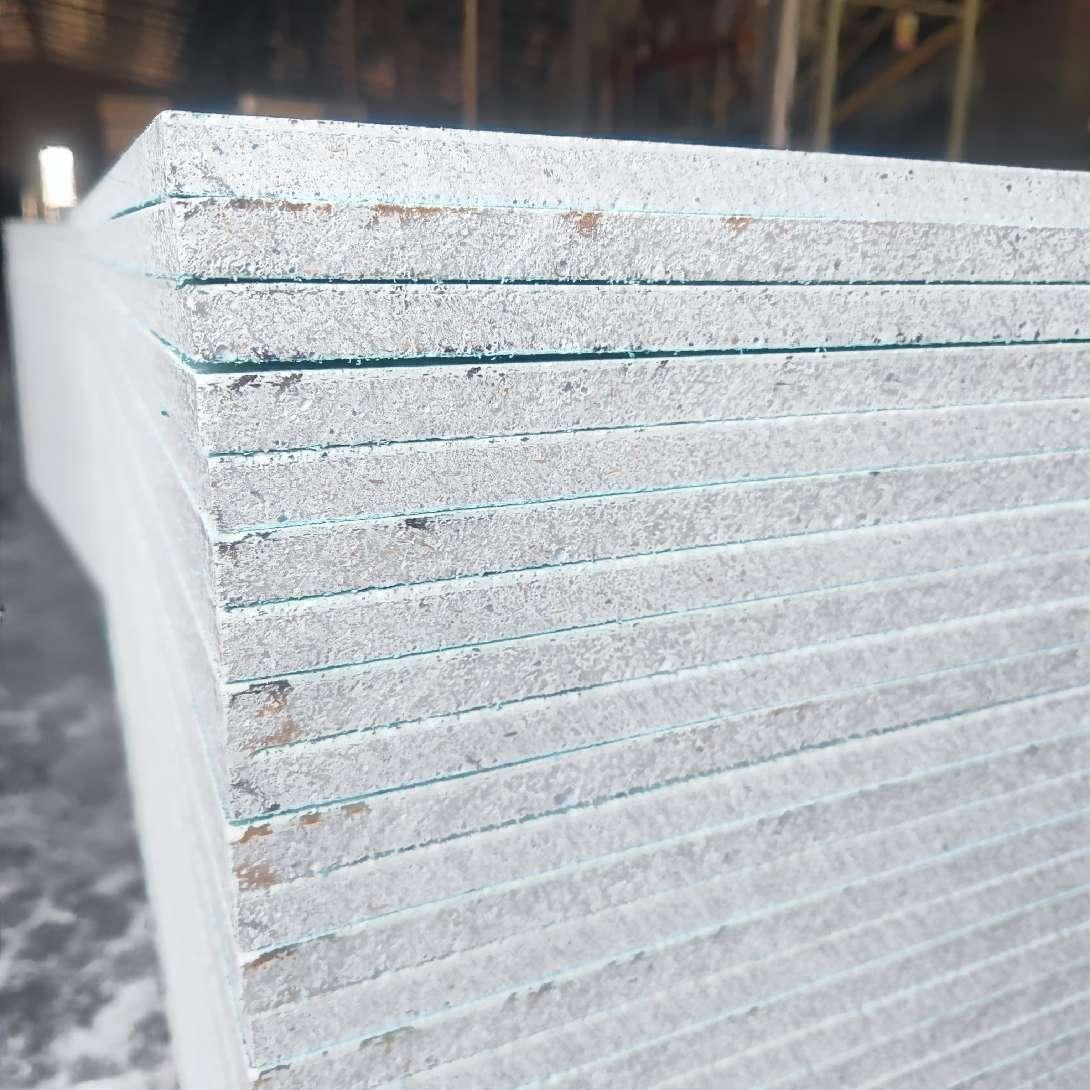

When the finished products are ready, we store them face-to-face. This method offsets the deformation forces between the boards, ensuring that they do not deform during transportation until they reach their destination. It's worth mentioning that if customers use magnesium boards as a substrate for decorative surfaces and the finished products are not used for an extended period, they should be stored face-to-face. This ensures that the magnesium boards do not show noticeable deformation when finally installed on the wall.

While deformation issues need attention, the force of deformation is much less than the adhesive strength of glue and the holding power of nails on the wall. This ensures that the boards do not deform once installed.

Post time: Jun-12-2024