Understanding how to judge the quality of MgO panels is crucial to ensure you purchase high-quality products. Here are some key factors and methods to help you make an informed decision when buying MgO panels.

1. Check the Raw Material Composition

High-Purity Magnesium Oxide: Quality MgO panels should use high-purity magnesium oxide to ensure excellent physical and chemical properties. You can request suppliers to provide raw material test reports to verify the purity of the magnesium oxide.

High-Quality Additives: Besides magnesium oxide, quality MgO panels should also contain high-quality fibers and fillers, which enhance the toughness and strength of the panels. Ensure that the supplier uses additives that meet the standards.

2. Evaluate the Production Process

Accurate Mixing Ratios: Quality MgO panels should have strict control over the mixing ratios of raw materials during production to ensure consistent quality of each panel. You can inquire about the supplier’s production processes and ratio control measures.

Even Mixing: The production process should use efficient mixing equipment to ensure even mixing of materials, reducing internal weak points in the panels. You can visit the factory to observe the production equipment and mixing process.

Proper Curing: Ensure that the panels are properly cured under suitable temperature and time conditions to enhance their strength and stability. Ask the supplier about their curing processes and quality control measures.

3. Inspect Quality Test Reports

Comprehensive Testing: Quality MgO panels should undergo comprehensive quality testing, including compressive strength, bending strength, fire resistance, and water resistance. Request detailed quality test reports from the supplier to verify the performance of the panels.

High Standard Testing: Ensure that the supplier adopts high-standard quality testing procedures and equipment to promptly detect and address potential defects in the panels. You can ask to see the testing equipment and standards.

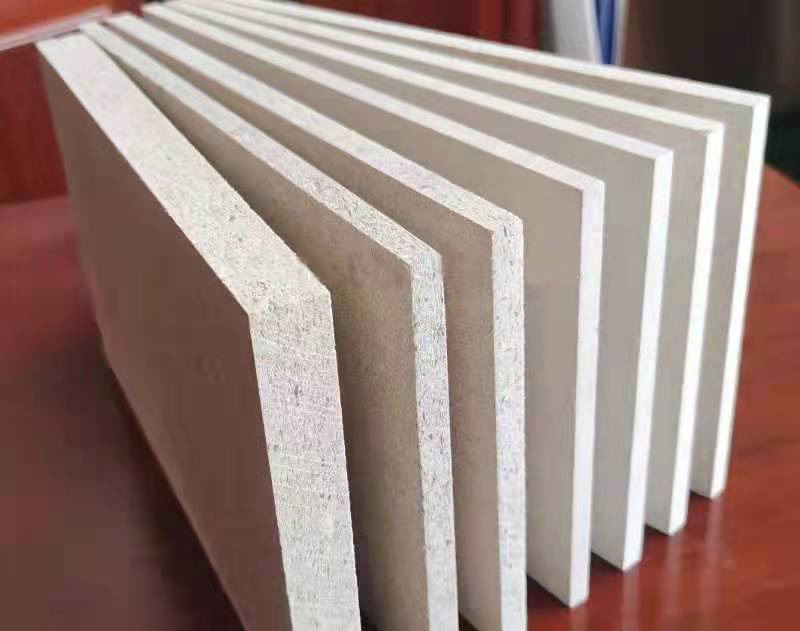

4. Observe the Appearance Quality

Surface Smoothness: Quality MgO panels should have smooth and flat surfaces without noticeable bumps or waves. Visually inspect the panel surfaces to ensure their quality.

Color Consistency: Panels from the same batch should have consistent color without noticeable color differences. Inconsistent color might indicate uneven material mixing or unstable production processes.

Edge Integrity: Check whether the edges of the panels are straight without damage or missing corners. Uneven edges can affect installation and service life.

5. Request Sample Testing

Before making bulk purchases, you can request the supplier to provide samples for testing. By practically testing various performance aspects such as strength, fire resistance, and water resistance, you can determine if the quality meets your needs.

Conclusion

By following these methods, you can better judge the quality of MgO panels and ensure you purchase high-quality products. Focusing on raw materials, production processes, quality testing, appearance quality, brand reputation, and sample testing during the selection process can effectively prevent the purchase of substandard MgO panels and ensure the smooth progress of your construction project.

Post time: Jun-21-2024