Low Carbon & Environmental: Belonging to New Low Carbon Inorganic Gel Material

From the carbon emission factor index data, ordinary silicate cement has a carbon emission factor of 740 kg CO2eq/t; gypsum has 65 kg CO2eq/t; and MgO boards have 70 kg CO2eq/t. Comparatively, MgO boards significantly reduce carbon emissions during production.

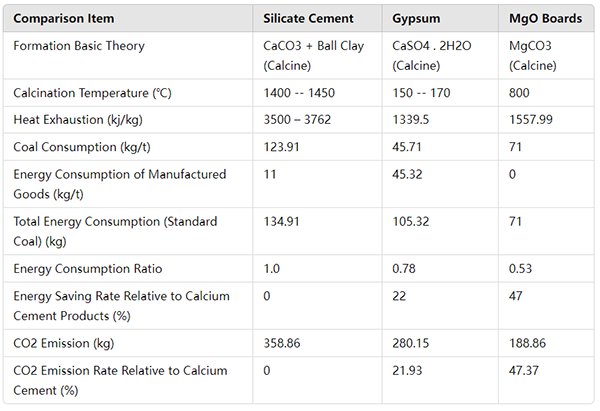

Production Energy Consumption Comparison

Conclusions:

1.The thermal energy consumption of the raw material production of MgO boards is much lower than that of calcium cement and close to that of gypsum production.

2.The production of MgO board products basically consumes no heat energy.

3.The total energy consumption of MgO boards is about half that of calcium cement and about two-thirds lower than that of gypsum; the CO2 emission is about half that of calcareous cement and two-thirds that of gypsum.

Carbon Absorption

5% of the world's total CO2 emissions come from the traditional cement industry, and each ton of cement clinker produced generates 0.853 tons of direct CO2 emissions and about 0.006 tons of indirect CO2 emissions. MgO boards, when placed in the air, will absorb a large amount of CO2 to form magnesium carbonate, magnesium carbonate trihydrate, basic magnesium carbonate, and other hydration compounds. When MgO boards are mixed with water for construction, each ton of cement can absorb 0.4 tons of carbon dioxide. Promoting and encouraging the application of MgO boards can be conducive to carbon reduction and better achievement of the dual carbon goals.

Post time: Jun-14-2024