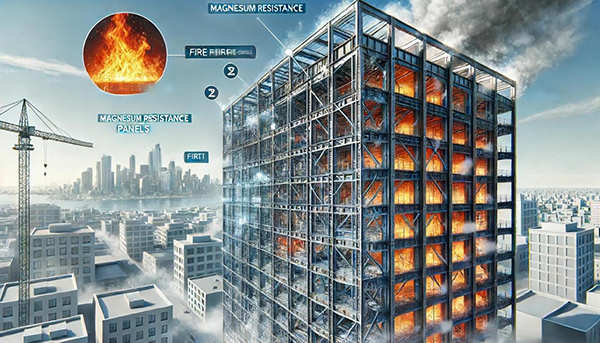

Magnesium Oxide Panels Meet All Application Requirements for Low Carbon, Green & Fireproof Buildings: Low Carbon, Fireproofing, Environmental, Safety & Energy Conservation

Outstanding Fireproof Performance:

Magnesium oxide panels are non-combustible class A1 building materials with superior fire resistance. Among the A1 grade inorganic fire retardant boards, magnesium oxide panels exhibit the highest fire performance, the highest fire temperature resistance, and the strongest fire resistance, making them the best fire-retardant building material available.

Ideal Fire Protection Material for Light and Heavy Steel Structure Systems:

Steel structure prefabricated buildings are a global development trend, but steel as a building material, especially in high-rise heavy steel structures, poses significant fire prevention challenges. The mechanical properties of steel, such as yield point, tensile strength, and elastic modulus, decrease sharply with increasing temperature. Steel structures typically lose their bearing capacity at temperatures between 550-650°C, leading to significant deformation, bending of steel columns and beams, and ultimately, the inability to continue using the structure. Generally, the fire resistance limit of unprotected steel structures is about 15 minutes. Therefore, steel structure buildings require external protective wrapping, and the fire resistance and heat conductivity of this wrapping material directly determine the fire safety performance of the steel structure.

Thermal Conductivity:

The thermal conductivity of magnesium oxide panels is 1/2 to 1/4 that of Portland cement-based boards. In the event of a fire, magnesium oxide panels significantly enhance the fire resistance time of steel structure buildings, allowing more time for fire rescue and preventing serious damage such as deformation.

Fire Resistance Temperature:

Magnesium oxide panels have a fire resistance temperature of over 1200°C, while Portland cement-based boards can only withstand temperatures of 400-600°C before experiencing explosive cracking and losing their fire resistance protection for steel structures.

Fire Retardant Mechanism:

The molecular crystal structure of magnesium oxide panels contains 7 crystal waters. In the event of a fire, these panels can slowly release water vapor, effectively delaying the transmission of heat from the fire point and protecting the fire safety of building components.

Magnesium oxide panels offer exceptional fireproof performance, making them an ideal choice for enhancing the safety and resilience of modern buildings, particularly those incorporating steel structures. Their superior fire resistance, low thermal conductivity, and innovative fire retardant mechanism ensure that buildings are better protected in the event of a fire, contributing to safer and more sustainable construction practices.

Post time: Jun-14-2024