The characteristics of the molecular structure of butyl rubber determine that it will generate strong internal friction when it encounters vibration, so that it can play a good damping role. Benefit from this, what effect will the butyl adhesive have on the sound absorption and damping of the board?

As a company that is deeply involved in the field of sound absorption of panels, Mr. Zhang of Shenzhen has carried out a number of tests with our butyl adhesive. Thank you for the test results provided by Mr. Zhang.

After the butyl adhesive is applied to the surface of the stone powder material, a layer of aluminum honeycomb panel is superimposed. Then heat the slate to 140°C, scrape the butyl rubber evenly, and press it to fit. At this time, the adhesive area between the two boards will reach 50 square centimeters. Through the peel test, it can be seen that the butyl glue firmly bonds the two boards of different materials together, and the bonding force is very ideal.

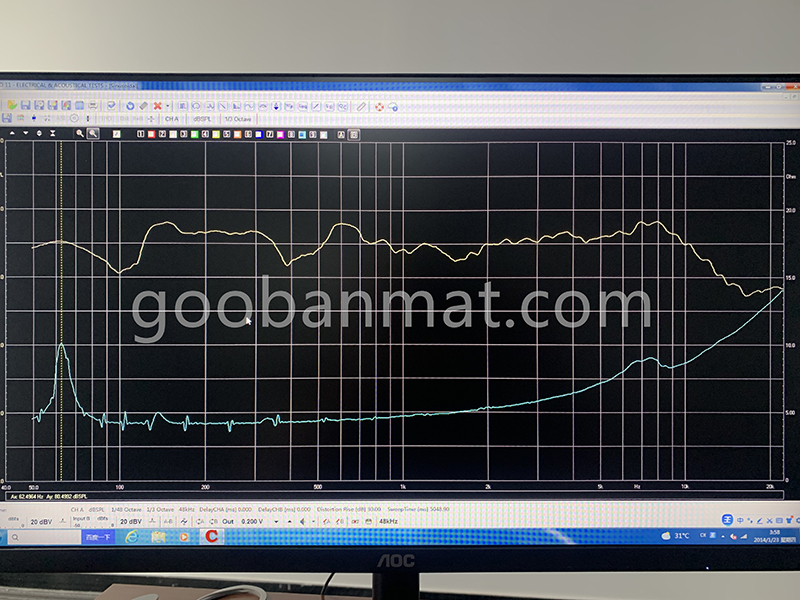

The next step is to test the damping effect of the experimental laminated sheet on the sound of different frequencies through the electro-acoustic system.

Preliminary experimental data show that butyl rubber has a good damping effect on low-frequency sound when it is sandwiched between the rock slab and the honeycomb panel, but the damping effect on high-frequency sound is limited, and further optimization is required.

After Mr. Zhang fed back the test results, we discussed the relevant proportions of the butyl adhesive formulation, and decided to adjust the rubber proportions and the mixing temperature at the same time. Make the sample as soon as possible and mail it to Mr. Zhang for the second test.

If you have similar application requirements or good suggestions, please contact us and look forward to communicating with you!

Post time: Sep-22-2022