One Board Supporting the Sky

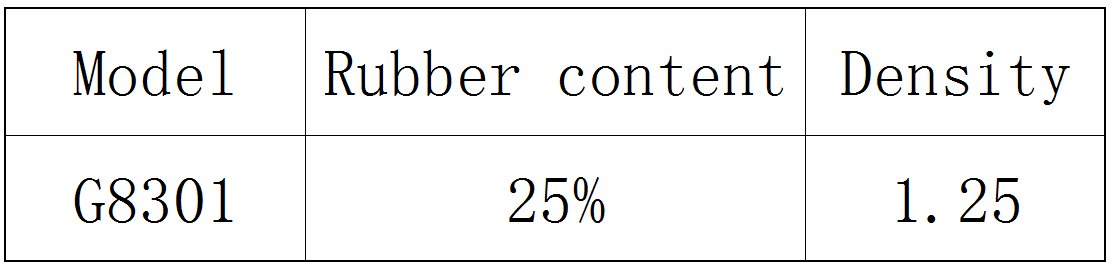

OEM/ODM Manufacturer Butyl Strip - G1031 Butyl Adhesive with Rubber Content Up to 25% – Gooban

OEM/ODM Manufacturer Butyl Strip - G1031 Butyl Adhesive with Rubber Content Up to 25% – Gooban Detail:

Introduction To Production Line

The company now has 10 domestic advanced production lines for mixing butyl rubber, with an annual output of 10000 tons. The patented formula is provided by Qingdao University of science and technology. After special process flow, its products have excellent adhesion, weather resistance, aging resistance and excellent waterproof and sealing properties.

It is mainly used for waterproof butyl tape coating, single-sided and double-sided self-adhesive waterproof coiled material coating, lap tape coating, etc., and can be produced according to the color specified by customers.

Rubber Mixing Process Conditions

Butyl rubber has low cohesion and poor self-adhesive property. The rubber is easy to be broken, and the process of regrouping into a whole is very slow. Therefore, higher mixing temperature and longer mixing time are required during mixing. During the mixing process, 2ylyy114wfm paid attention to the change of mixing temperature in time and strictly controlled the mixing temperature to avoid the influence of too high or too low temperature on the quality of mixed rubber and finished products. When butyl rubber is mixed by internal mixer, the mixing temperature is generally controlled at 150 ° C to promote the uniform dispersion of the compounding agent.

Internal mixer mixing: when mixing butyl rubber with internal mixer, properly increase the rubber loading capacity, which is greater than 10% – 20% of natural rubber; The pressure of upper top bolt is higher than that of lower top bolt during mixing. When the amount of compounding agent used in the formulation of butyl rubber products is large, two-stage mixing method or reverse mixing method can be used for the mixing process.

Product detail pictures:

Related Product Guide:

Our target should be to consolidate and enhance the top quality and service of current goods, in the meantime frequently create new products to satisfy diverse customers' calls for for OEM/ODM Manufacturer Butyl Strip - G1031 Butyl Adhesive with Rubber Content Up to 25% – Gooban , The product will supply to all over the world, such as: Guyana, Italy, Mexico, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.