One Board Supporting the Sky

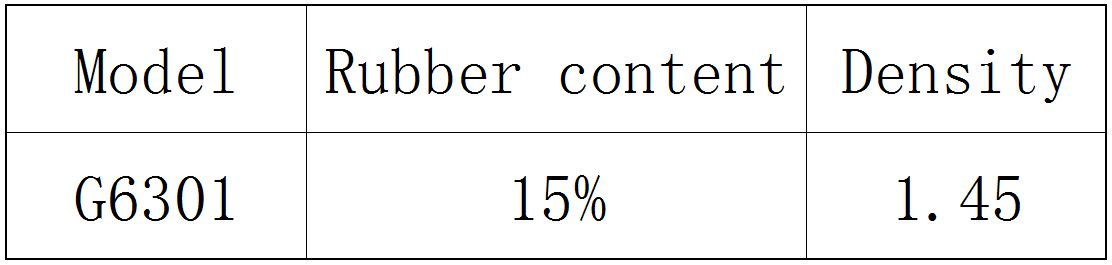

Online Exporter White Gloss Pvc Panels - G1031 Butyl Adhesive with Rubber Content Up To 15% – Gooban

Online Exporter White Gloss Pvc Panels - G1031 Butyl Adhesive with Rubber Content Up To 15% – Gooban Detail:

Formulation Design

Butyl rubber is widely used in manufacturing inner tube, anti vibration rubber, industrial rubber plate, medical rubber and many other aspects because of its unique properties. This paper mainly describes the influence of compounding agent on the physical properties of butyl rubber.

Carbon Black

The effect of carbon ink on the physical properties of ordinary butyl rubber is basically the same as that of halogenated butyl rubber. The effects of various carbon black on physical properties are as follows:

(1) The tensile strength and tear strength of vulcanizates of carbon black with small particle size such as saf (super wear-resistant furnace black), ISAF (medium and super wear-resistant furnace black), HAF (high wear-resistant furnace black) and MPC (miscible tank black) are larger;

(2) Ft (fine particle hot cracking carbon black), MT (medium particle hot cracking carbon black) and other carbon black with large particle size have large elongation of vulcanizate;

(3) No matter what kind of carbon black, with the increase of its content, the tensile stress and hardness of the vulcanizate increased, but the elongation decreased;

(4) The compression set of SRF (semi reinforced furnace black) vulcanizate is superior to that of other carbon black;

(5) The extruding performance of furnace carbon black is better than that of trough carbon black and hot cracking carbon black.

Application

It is widely used in civil buildings with general requirements for weather resistance, as well as damping gaskets of wall panels and automobile damping gaskets. Especially as a damping gasket, it gives full play to the damping characteristics of butyl rubber and greatly reduces the vibration of the environment.

Common Coating Production Process:

For damping gaskets and waterproof coiled materials, how can butyl rubber be coated on the substrate. The process is relatively simple: glue feeding – extrusion – Coating – slitting. The extrusion temperature is controlled at 90-100 ℃.

Figure 1-2-3-4

Product detail pictures:

Related Product Guide:

We stick to our enterprise spirit of Quality, Efficiency, Innovation and Integrity. We aim to create more value for our customers with our rich resources, advanced machinery, experienced workers and excellent services for Online Exporter White Gloss Pvc Panels - G1031 Butyl Adhesive with Rubber Content Up To 15% – Gooban , The product will supply to all over the world, such as: Hamburg, Amman, Sri Lanka, We pay high attention to customer service, and cherish every customer. We've maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!